Gas Mass Flowmeter Sensor MEMS Flow Sensing Chip LED Display Screen - MF4700Series

It is equipped with an RS485 communication module, facilitating centralized control and remote transmission

The sensing chip adopts thermal mass flow measurement, eliminating the need for temperature and pressure compensation, ensuring the high-precision measurement of the flowmeter

Multi-sensor integration has been achieved on a single chip, enabling its range ratio to reach 50:1 or even higher

- Quantity:

- - +

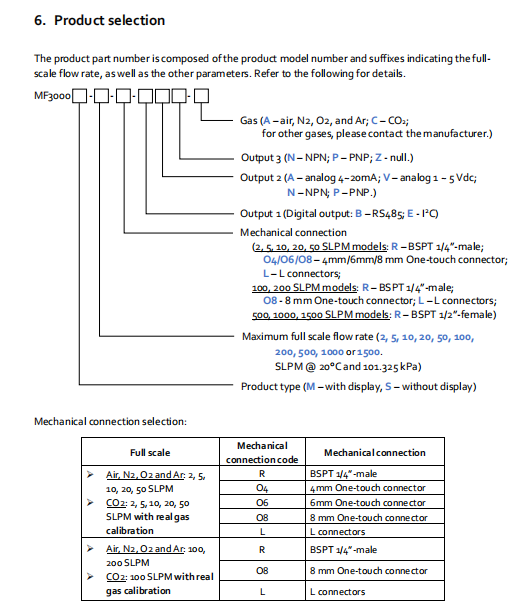

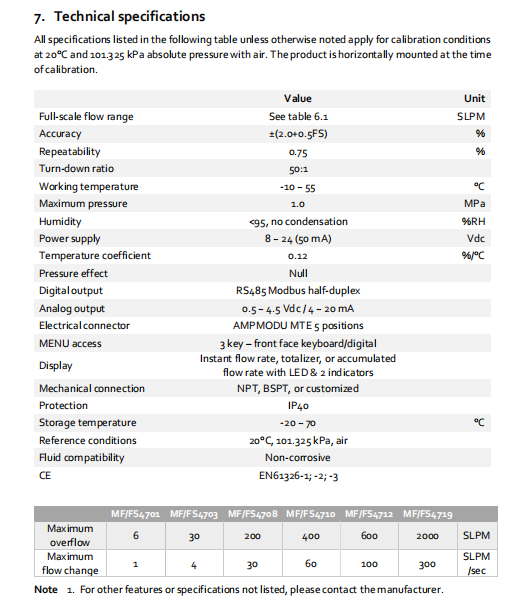

Product Specification

Product Introduction of Gas Mass Flowmeter MEMS Flow Sensing Chip LED Display MF4700 Series:

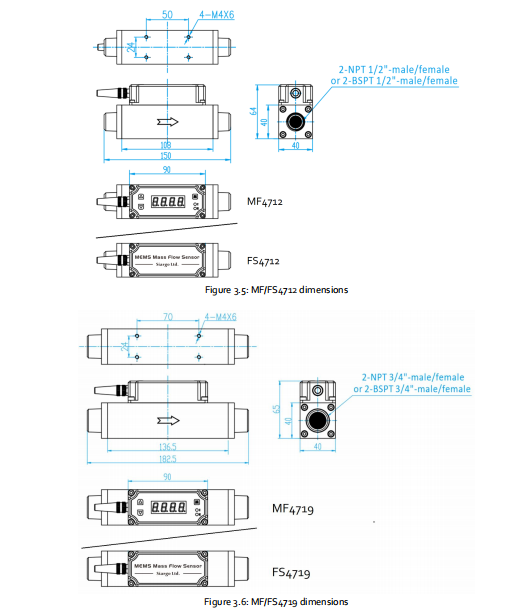

The MF/FS4700 series gas mass flowmeters are all made with the micro-electromechanical system (MEMS) flow sensing chips independently developed by our company, and are suitable for various clean and dry gases.

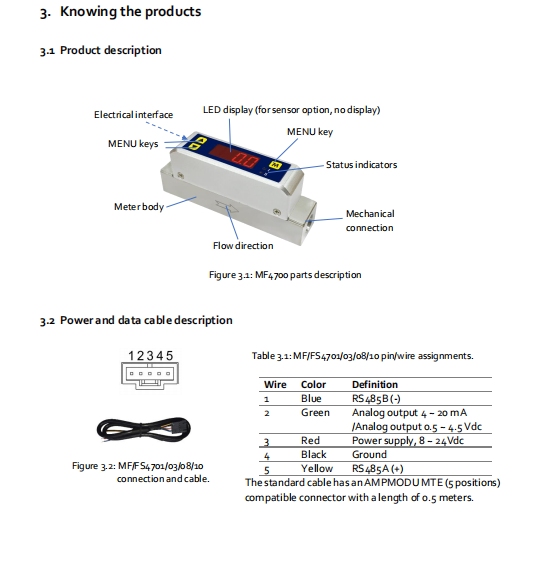

The MF/FS4700 features a clear and intuitive LED display that can show real-time traffic and cumulative total. The MF/FS4700 directly outputs mass flow rate without the need for temperature and pressure compensation. The MF/FS4700 is equipped with a key function, allowing users to adjust or query the parameters of the flowmeter on-site. It also features an RS485 network communication interface for remote control and system integration by users. The mechanical dimensions and flow range can be customized according to customer requirements.

Product features of the gas mass flowmeter MEMS flow sensing chip LED display MF4700 series:

The sensing chip adopts thermal mass flow measurement, eliminating the need for temperature and pressure compensation, ensuring the high-precision measurement of the flowmeter

Multi-sensor integration has been achieved on a single chip, enabling its range ratio to reach 50:1 or even higher

The output mode is flexible. It can either actively upload data through the communication interface or have the output data queried by the upper computer, or output linear analog voltage through the analog interface

The LED display shows the instantaneous flow rate and cumulative total, allowing the flowmeter parameters to be configured on-site with buttons

It can record the maximum and minimum values of the instantaneous flow since power-on and has an over-range indication function

It is equipped with an RS485 communication module, facilitating centralized control and remote transmission

The same gas path interface as the traditional rotameter

The mechanical dimensions and flow range can be customized according to the customer's requirements

If you cannot find what you want, you can entrust ISweek to source for you. Just click:

Sourcing Service